About FLASH:

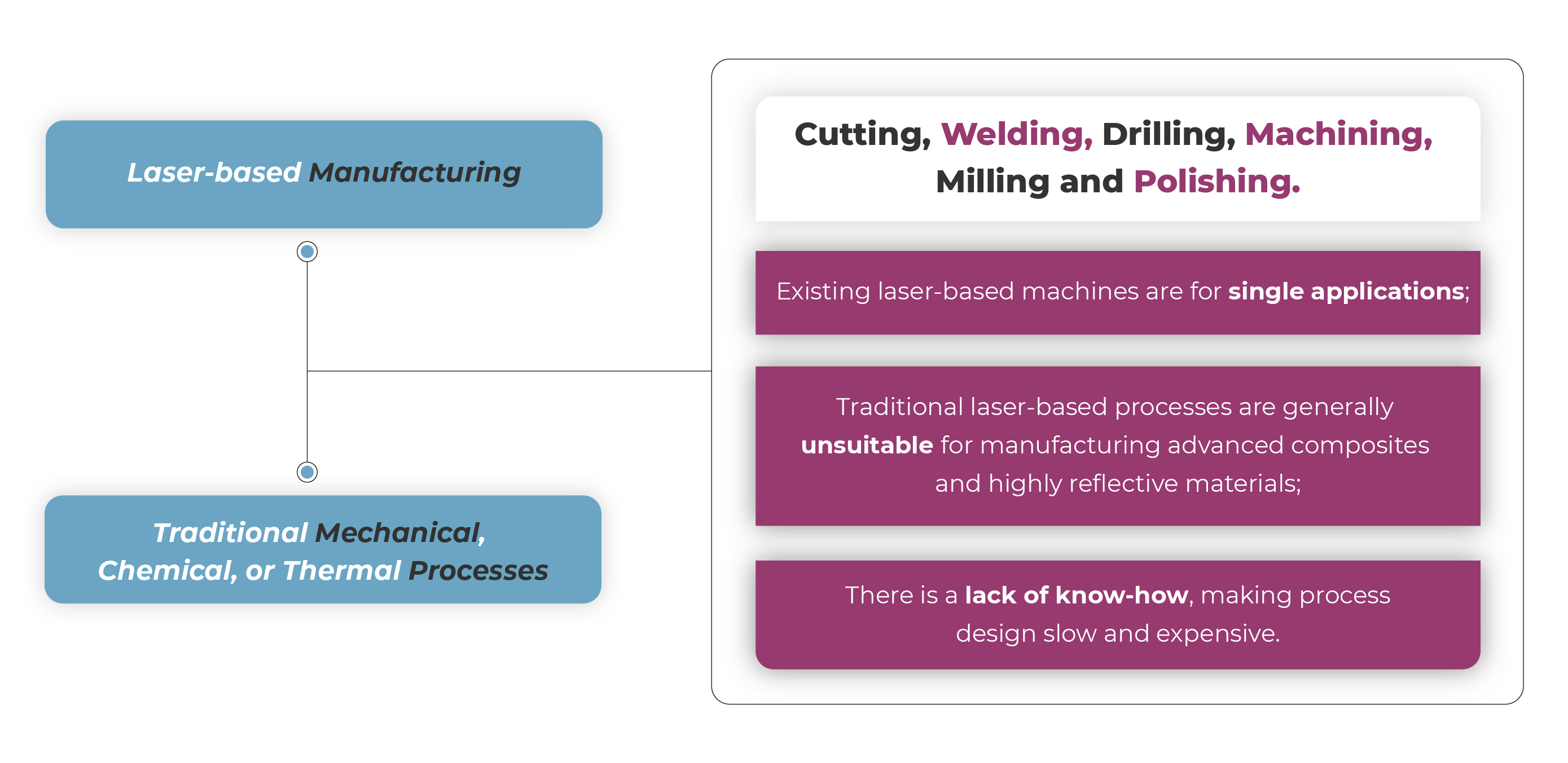

The FLASH project aims to revolutionize manufacturing by leveraging future-proof, highly customizable and energy-efficient laser-based production systems to achieve highly precise photon distribution, with applications in cutting, drilling, welding, cladding, and micro-machining.

The FLASH project lies in its ability to provide agility, speed, cost-effectiveness, material flexibility, and energy savings compared to

existing technologies.

Its capacity to rapidly reconfigure manufacturing processes, reduce cycle time, and minimize capital investment and space requirements positions it as a forward-looking solution for industries like medical, tooling, automotive, and e-mobility.

The FLASH project aims to pioneer the next generation of laser machining through four key technology developments:

Integration of Laser Sources and Beam Delivery Heads:

Develop a single laser module integrating three laser sources and three beam delivery heads, allowing multi-wavelength emission, broad pulse length regime, and dynamic beam shaping.

Dynamic Beam Shaping:

Implement adaptive energy distribution for dynamic beam shaping in a hybrid robotic/CNC platform, enhancing flexibility in manufacturing processes.

In-Process Monitoring and Control:

Incorporate in-process monitoring and control mechanisms, supported by an advanced digital infrastructure based on a cloud data management system, to ensure stable and efficient manufacturing.

Process Design for Laser-Based Manufacturing:

Integrate process design models using machine learning and a cloud data management system, aiming to minimize waste, defects, process costs, and energy consumption.