The FLASH solution introduces the potential for emerging business models.

The FLASH solution introduces the potential for emerging business models by implementing flexible and customizable tools. This approach ensures modularity,

aligning the solution dynamically with market demands. Leveraging FLASH laser-based solutions aims to optimize machine utilization by keeping it consistently

engaged with various processes and accommodating market requests.

This strategy aims to maximize machine uptime, leading to a swift return on investment. Furthermore,

laser-based manufacturing can be easily integrated with digital manufacturing technologies, such as computer-aided design and simulation, to enable rapid prototyping

and iterative design. As a result, European manufacturers gain the agility to swiftly adapt to evolving market requirements, thereby reducing the time-to-market for new products.

Provide agility, speed, cost-effectiveness, material flexibility, and energy savings compared to existing technologies.

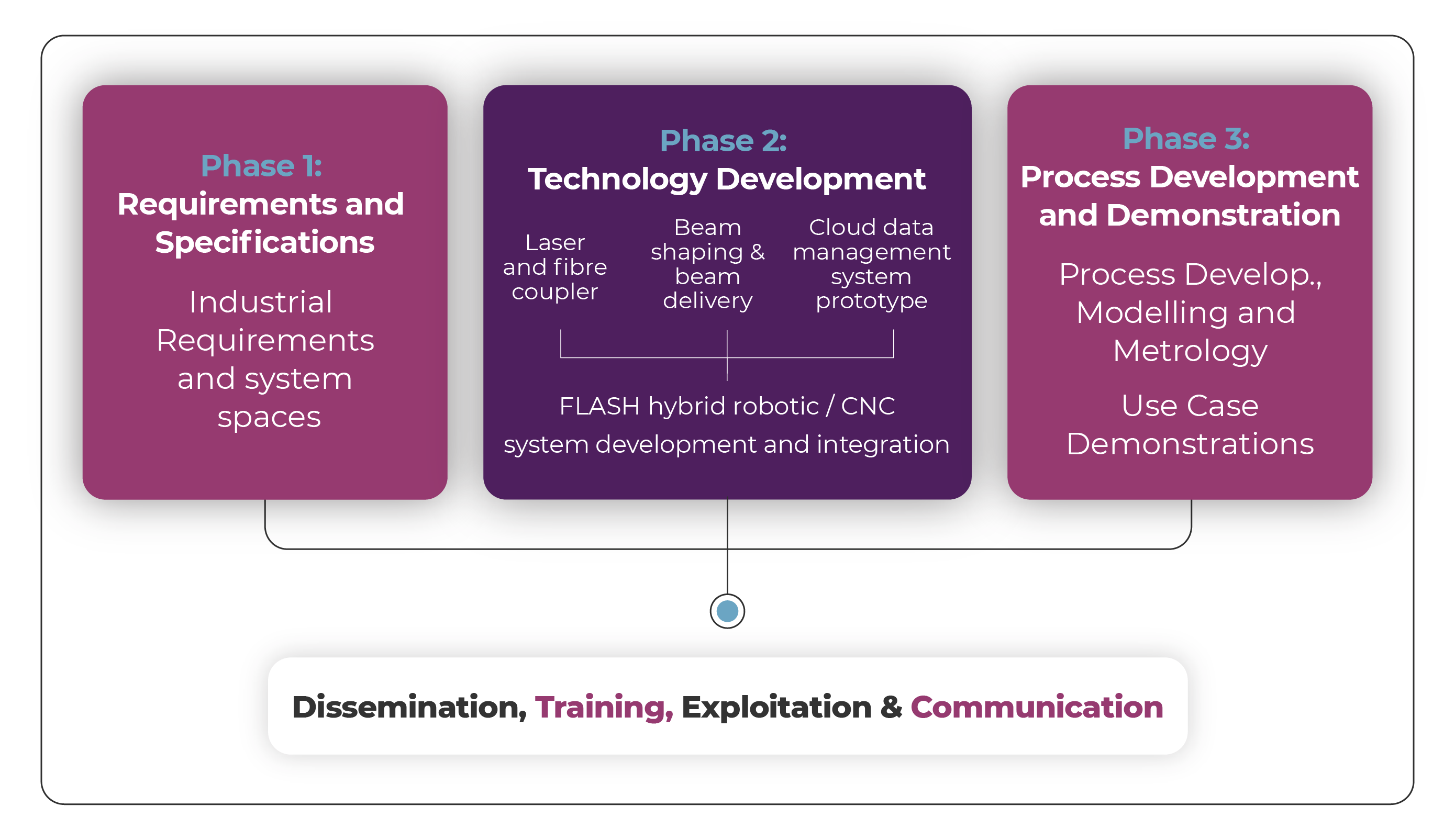

Integration of Laser Sources and Beam Delivery Heads:

Develop a single laser module integrating three laser sources and three beam delivery heads, allowing multi-wavelength emission, broad pulse length regime, and dynamic beam shaping.

About FlashDynamic Beam Shaping:

Implement adaptive energy distribution for dynamic beam shaping in a hybrid robotic/CNC platform, enhancing flexibility in manufacturing processes.

About FlashIn-Process Monitoring and Control:

Incorporate in-process monitoring and control mechanisms, supported by an advanced digital infrastructure based on a cloud data management system, to ensure stable and efficient manufacturing.

About FlashProcess Design for Laser-Based Manufacturing:

Integrate process design models using machine learning and a cloud data management system, aiming to minimize waste, defects, process costs, and energy consumption.

About Flash